navaltorreiro

Naval Torreiro are specialists in the manufacture of water treatment equipment. We work in the naval, offshore, industrial and service sectors, with almost 40 years of experience, which makes us one of the best in our field.

Products for fresh water generation equipment by evaporation or reverse osmosis, as well as anti-fouling equipment for the generation of sodium hypochlorite by electrolysis, stand out.

Español – Descarga

English – Download

Freshwater generators by evaporation

El generador de agua Fontemar® está diseñado para transformar agua salada del mar en agua dulce, apta para el uso humano e industrial. Este equipo puede ir tanto a bordo de los buques como en instalaciones de tierra.

El equipo trabaja bajo el principio de destilación en vacío. En el interior de la carcasa el agua salada hierve a baja temperatura (debido al vacío) y el vapor de agua producido, al elevarse, atraviesa el separador y llega al condensador. El agua generada, después de la condensación, es enviada a través de una bomba al tanque almacén.

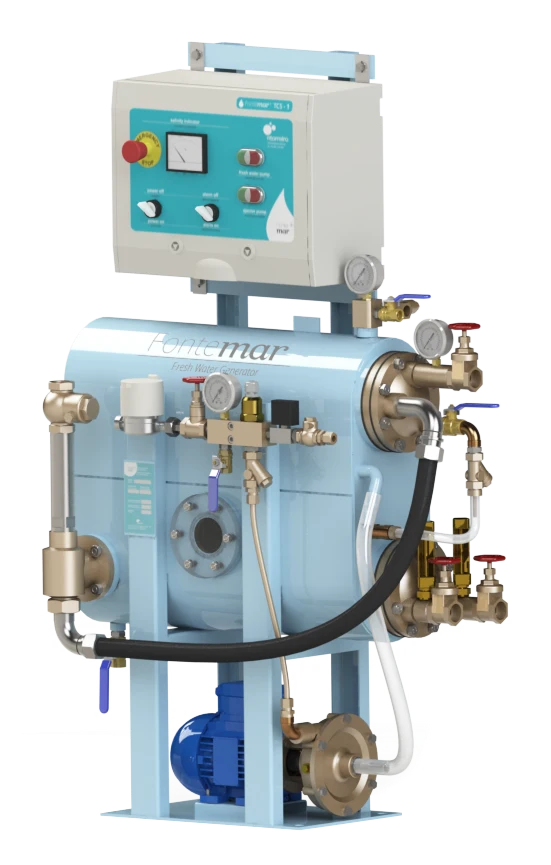

The Fontemar® water generator is designed to transform sea salt water into fresh water, suitable for human and industrial use. This equipment can be used both on board ships and in shore installations.

The unit works on the principle of vacuum distillation. Inside the casing, the salt water boils at a low temperature (due to the vacuum) and the water vapour produced, on rising, passes through the separator and reaches the condenser. The water generated, after condensation, is sent through a pump to the storage tank.

Español – Descarga

English – Download

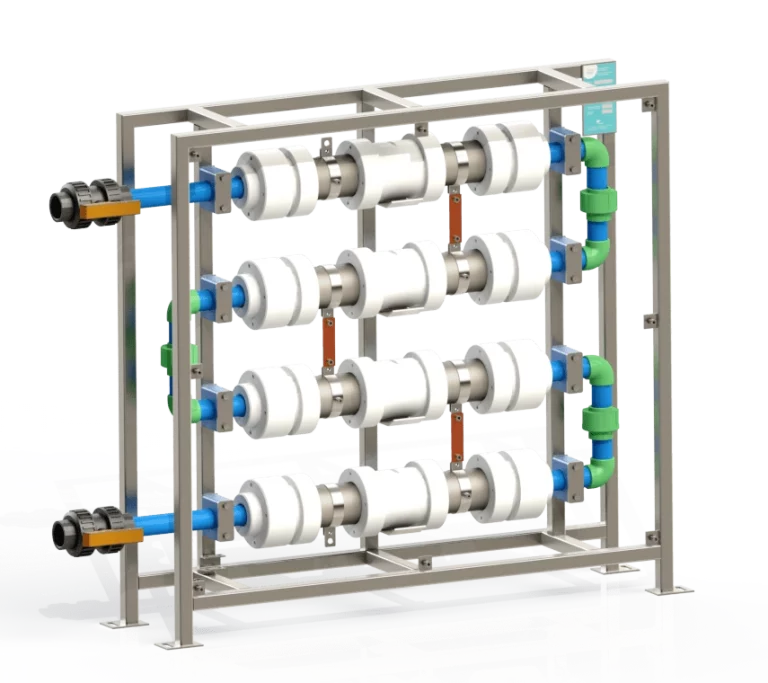

Freshwater generators by reverse osmosis

El equipo de ósmosis inversa Osmomar® está diseñado para trabajar tanto en instalaciones marinas como terrestres. Su funcionamiento se basa en el proceso natural de ósmosis que se produce en los seres vivos, por el cual dos soluciones de diferente salinidad, puestas en contacto a través de una membrana semipermeable, tienden a igualar sus concentraciones, quedando las sales retenidas en la membrana, permitiendo así el paso del agua sin salinidad.

En la ósmosis inversa, sólo una parte del flujo de alimentación atraviesa la membrana, constituyendo la producción, mientras que el resto se elimina sin atravesar la membrana, constituyendo el rechazo.

The Osmomar® reverse osmosis equipment is designed to work in both marine and land-based installations. Its operation is based on the natural process of osmosis that occurs in living beings, by which two solutions of different salinity, placed in contact through a semi-permeable membrane, tend to equalise their concentrations, with the salts being retained in the membrane, thus allowing the passage of water without salinity.

In reverse osmosis, only a part of the feed flow passes through the membrane, constituting the production, while the rest is removed without passing through the membrane, constituting the rejection.

Español – Descarga

English – Download

Español – Descarga

English – Download

Español – Descarga

English – Download

Anti-fouling system sodium hypochlorite

En Naval Torreiro hemos desarrollado el equipo Chloromar®, la solución definitiva para evitar las incrustaciones de algas, moluscos y crustáceos en los circuitos de agua salada de los barcos, el mantenimiento de piscinas y el tratamiento de aguas residuales.

Chloromar® es un sistema de desinfección seguro y sin problemas de mantenimiento, que evita el uso de cloro gas y los inconvenientes de su almacenamiento y manipulación. El funcionamiento del equipo es sencillo y económico, además de más saludable y ecológico que otros sistemas.

At Naval Torreiro we have developed the Chloromar® equipment, the definitive solution to prevent algae, molluscs and crustaceans fouling in the salt water circuits of boats, swimming pool maintenance and waste water treatment.

Chloromar® is a safe and maintenance-free disinfection system that avoids the use of chlorine gas and the inconvenience of storage and handling. The operation of the equipment is simple and economical, as well as healthier and more environmentally friendly than other systems.

Heat exchangers

Manufacturing, design, repair and maintenance

Since 1983, we have been manufacturing hundreds of heat exchangers per year for our Fontemar® freshwater generators. This expertise is transferred to the manufacture and repair of other types of equipment.

We offer manufacturing and repair services for different types of heat exchangers, mainly shell and tube, according to customer specifications:

- Retubing

- Repair of housings

- External and internal coating of the casing

- Manufacture of new heat exchangers

- Supply of tubes according to specifications

- Hydraulic tests

- Welding tests

Technical service and advice

With more than four decades of dedication, we provide our customers with first-class technical service and advice. Our highly trained team of professionals provides appropriate solutions and guides our customers at every stage, from inception to after-sales service.

In addition, we are confident in the quality of our products and offer excellent warranty conditions for the peace of mind of our customers.

Spare parts

We keep a large stock of spare parts in our facilities to guarantee the immediate availability of the necessary components in case of wear and tear or maintenance.

In addition, our equipment always includes spare parts to cover any possible need for a period of time. We take care of determining the spare parts needed in each case in order to provide a fast and efficient service.

About us

We are a company with a great passion for what we do and we have been proving it for 40 years in the water treatment equipment manufacturing industry.

Our experience and dedication is reflected in each of our products, from freshwater evaporation and reverse osmosis equipment to anti-fouling systems using sodium hypochlorite generation by electrolysis, to tube heat exchangers and post-treatment systems such as mineralisers or UV sterilisers, among many other things. We are located in the POCOMACO industrial estate in A Coruña, and we are committed to providing high quality water treatment solutions for our customers.

In our company, excellence is our priority and it shows in every detail of our products and services.

At Naval Torreiro, we are committed to providing high quality products and services to our customers by implementing and complying with quality practices and standards in all areas of our operation.

We continuously evaluate and improve our processes to ensure customer satisfaction and comply with applicable regulatory requirements. In addition, we comply with ISO 9001 standards, ensuring a robust and effective quality management system.

At our company, we value ethics, responsibility and quality in everything we do. We strive to build strong, long-lasting relationships with our customers, providing exceptional service and delivering innovative and effective solutions.

We promote a safe and collaborative working environment for our team and foster a culture of continuous improvement and learning. In addition, we are committed to sustainable development and environmental protection in all our operations.

Some of our clients

Contact us

If you would like more information about any of our products or services, please do not hesitate to send us a message by filling in the details below, we will be happy to help you: